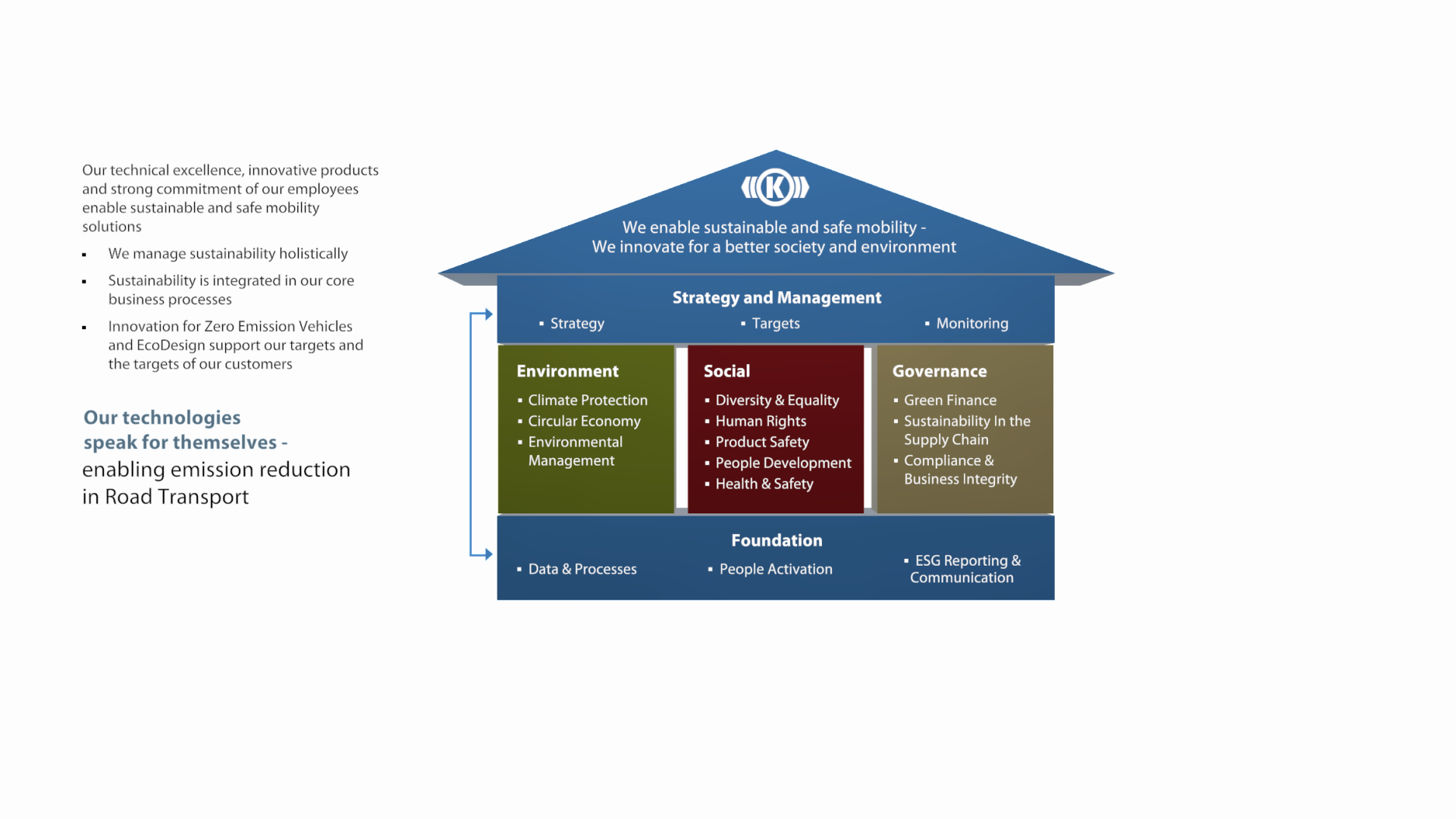

“Zero emissions” is currently the biggest challenge facing the entire mobility sector. Our vision is to revolutionize the transportation industry by developing and implementing innovative and emission-free e-mobility solutions.

E-Mobility as the key to the future

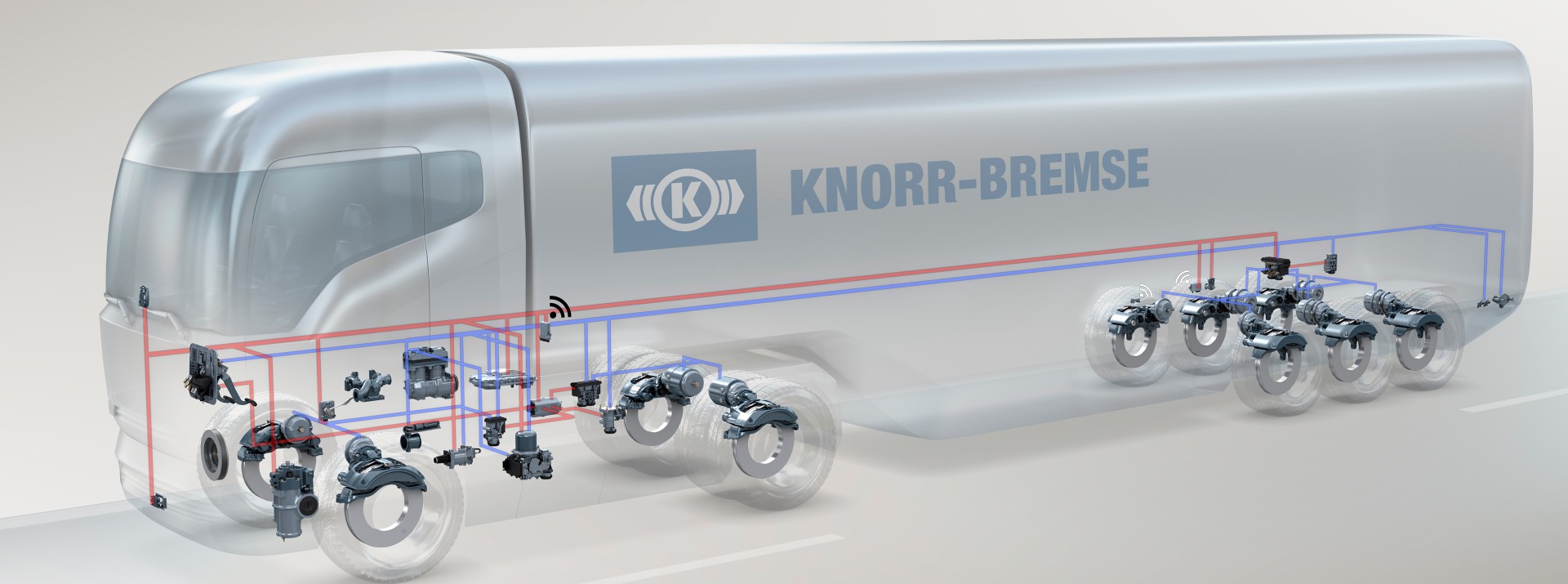

E-Mobility is currently the most important, but not the only, future technology in the “zero emissions” mission. To date, zero emissions has primarily focused on electrically powered vehicles and the reduction of CO2 emissions. However, in order to achieve the challenging EU targets for climate neutrality and the reduction of greenhouse gases, all forms of emissions reduction are important. Our e-mobility products are therefore also developed with the following aspects in mind:

- Particle reduction: development of Euro7-compliant braking solutions. Focus on emission reduction and emission-free braking

- Oil reduction: new technologies meet the sustainability requirements of our customers through efficient drive technologies

- Noise reduction: reducing noise in subsystems improves comfort for drivers and residents, thereby increasing the quality of life in urban areas

In order to realize our vision of zero-emission road transport, we are therefore working with customers and partners to develop solutions that meet the Paris climate targets and are firmly rooted in our brand strategy. We support vehicle manufacturers in the technology-open development of maximally efficient and emission-reduced commercial vehicles with our holistic product portfolio and see the future of the drivetrain in a variety of ways.

The Green Transformation

Zero emissions in road traffic is our ultimate goal - as a reliable partner for our customers and for a greener and more sustainable future.