Development Focus eCUBATOR

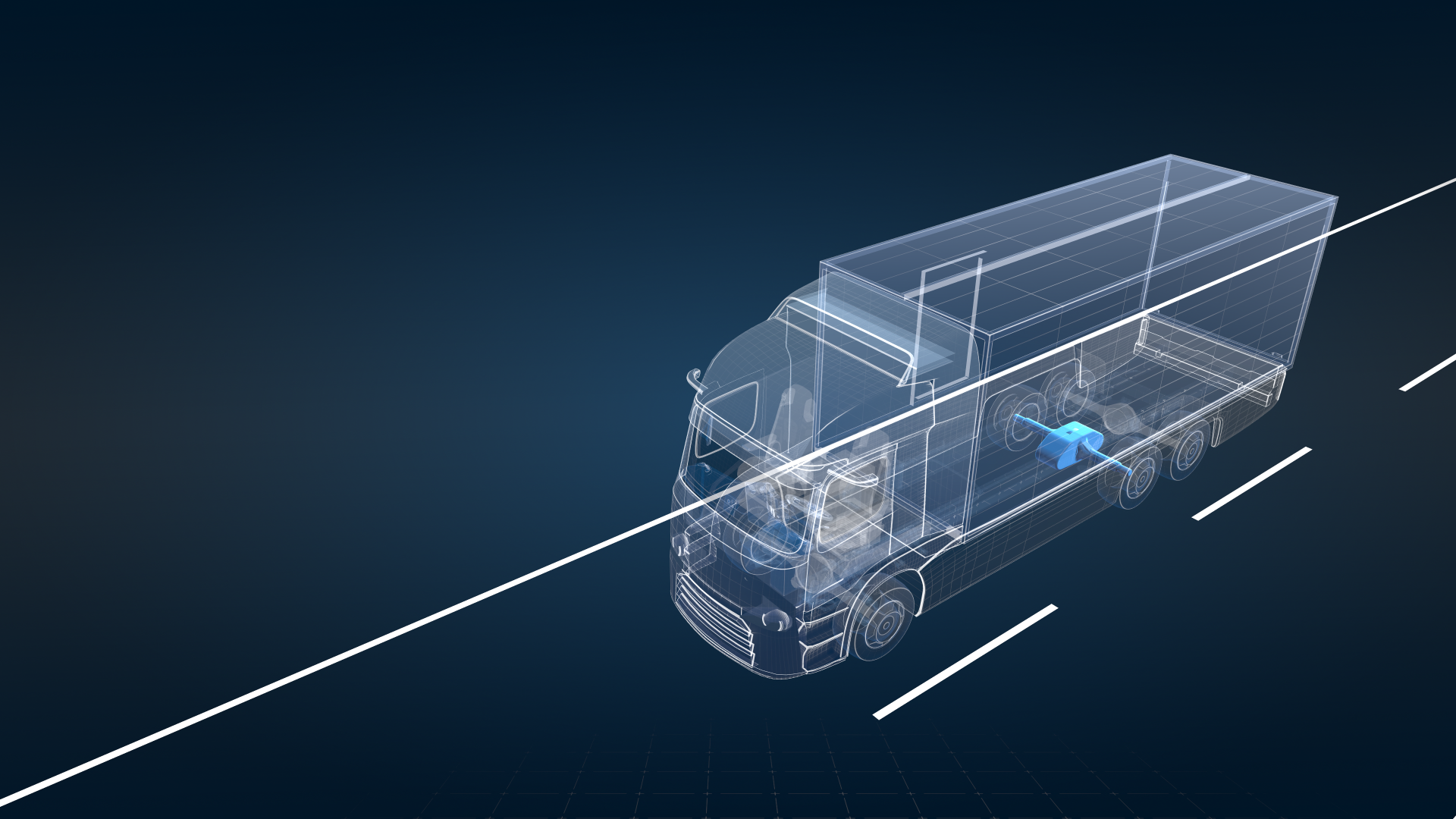

Electric Vehicle Motion Control (eVMC)

The eVMC software optimizes the longitudinal dynamics of electrically powered commercial vehicles, resulting in energy-efficient driving and stable handling. The eVMC achieves best-in-class energy recovery during braking maneuvers by optimizing the vehicle’s existing brake blending strategy. To do so, the eVMC uses the vehicle dynamics monitoring function on both tractor and trailer to predictively determine the tractor-trailer unit’s stability limits. The motion control functions can be integrated into all new eDrive configurations anywhere in the world, from single, centralized electric motors to multi-motor layouts with axle-mounted or wheel-mounted drives on one or more powered axles.

Redundant Power Management System (rPMS)

The redundant Power Supply System (rPMS) is a solution for safety-related systems. These include the Electric Power Steering (EPS) system in electrified commercial vehicles, as well as brake control systems, ECUs and sensors for automated driving. Two independent power supply circuits deliver fail-safe operation in highly automated commercial vehicles by ensuring that systems remain highly available.

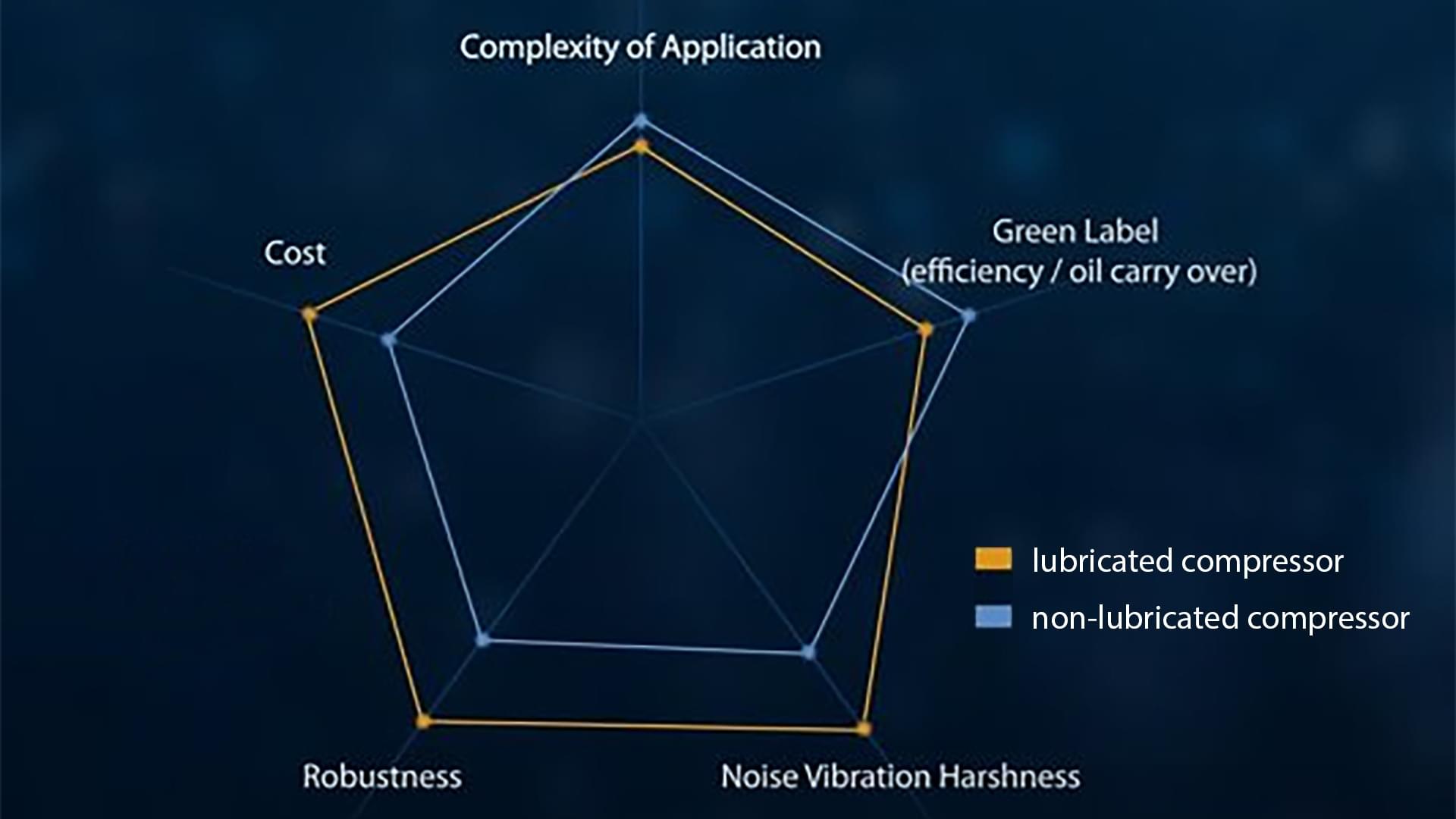

E-Compressor

Knorr-Bremse is scouting and analyzing various compressor technologies by conducting a comprehensive benchmarking. We do understand future electric vehicle requirements and work on a robust, oil free compressor concept as an addition to our existing product portfolio enabling us to meet individual customer needs.

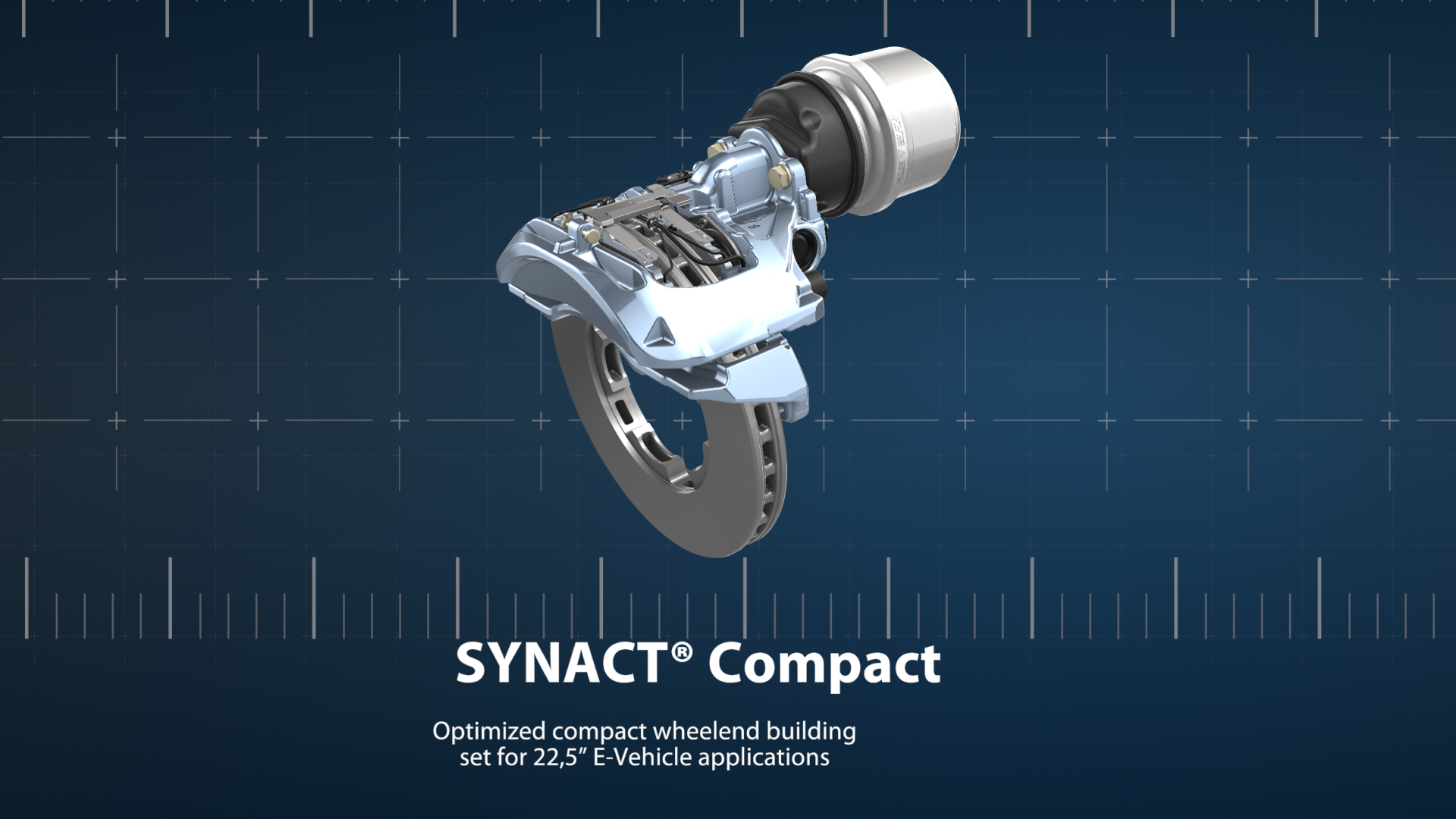

EV-Wheelend

Knorr-Bremse is examining various approaches in the EV-Wheelend with the common goal of offering the best possible customer solutions for the following selected main development fields: "E-Integration, Emission, Efficiency, and Electrification".

Electro-Mechanical Braking System (EMBS)

For Electric Vehicles the onboard available electric energy offers good opportunities for electro-mechanical actuation in every system. But shifting to EMBS is not only replacing the actuator, but the whole brake system shall also be reconsidered including Brake Control and Energy Supply. EMBS provides technical advantages in terms of installation space, noise and control precision.

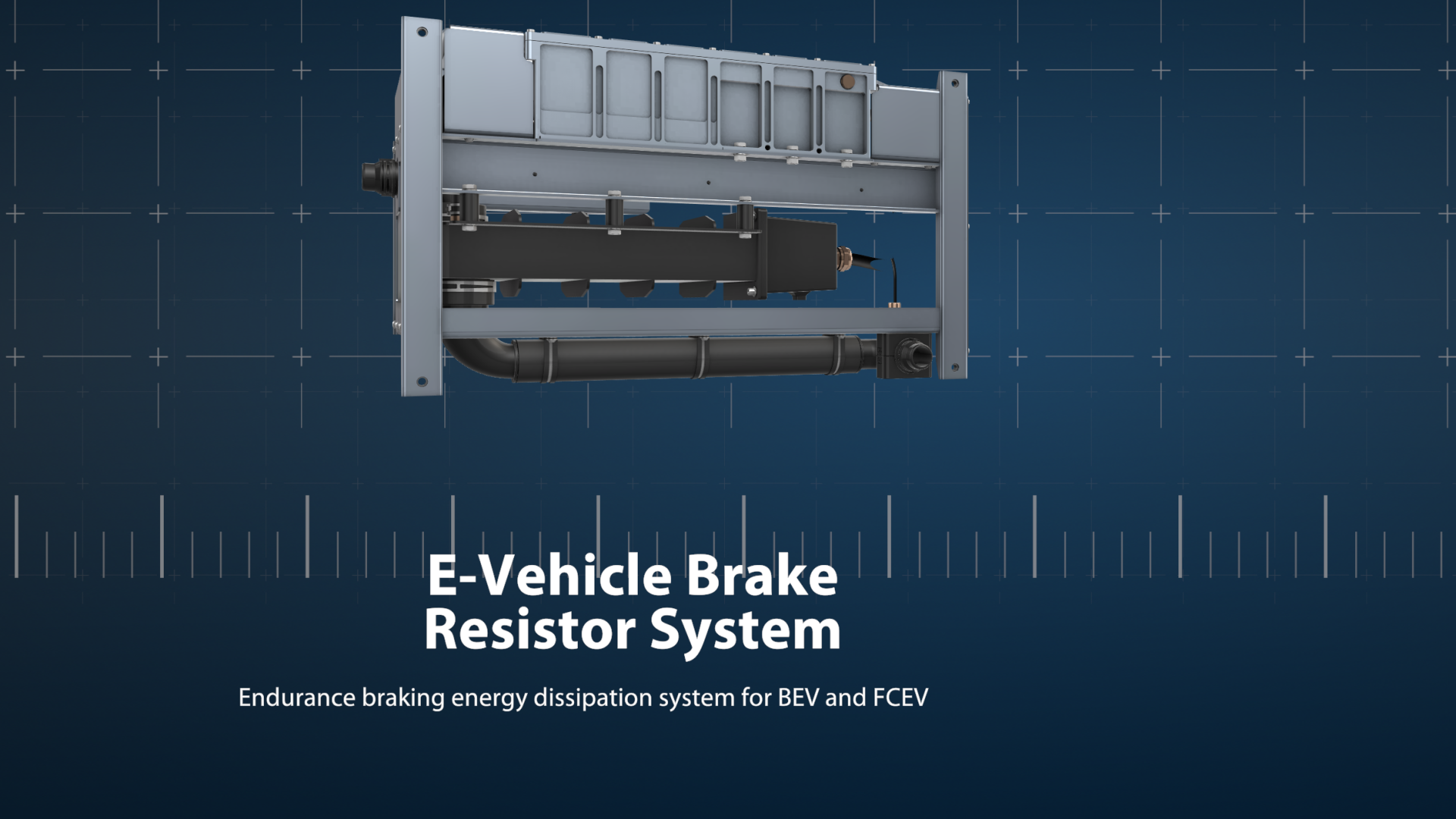

Fuel Cell Technology

The hydrogen economy is in a strong development phase and is being strongly promoted by governments worldwide to support decarbonization in various industries. Fuel cell technology will play an important role in the heavy-duty sector. From 2030, a significant increase in fuel cell trucks is expected with this established infrastructure. Knorr-Bremse is currently investigating ways of contributing its expertise to this new segment and expanding it through other opportunities.

Knorr-Bremse holisitic E-Mobility Product Portfolio